Biopolymers have been proposed as a replacement for synthetic polymers used in tissue repair because of their nontoxic nature. The review provides an up-to-date summary of the status and future prospective applications of micro- and nanocellulose-based scaffolds for tissue engineering.īiopolymers are naturally sourced and have been reported to have good biocompatibility with the human system. The review concludes with future potential research on cellulose micro- and nano-based scaffolds. It also analyses the relationship between the method of fabrication and properties of the fabricated scaffold. This review presents a critical overview of micro- and nanoscale cellulose-based materials used for scaffold preparation. Its unique physical, chemical, mechanical, and biological properties offer some important advantages over synthetic polymer materials. The discovery of nanocellulose has further improved the usability of cellulose as a reinforcement in biopolymers intended for scaffold fabrication. Cellulose in scaffold forming has attracted a lot of attention because of its availability and toxicity properties. Micro- and nanocellulose-based materials are at the forefront of scientific development in the areas of biomedical engineering. Tissue engineering techniques for scaffold forming with cellulose-based material is at the forefront of present-day research. Production of scaffold for tissue repair is a major part of tissue engineering.

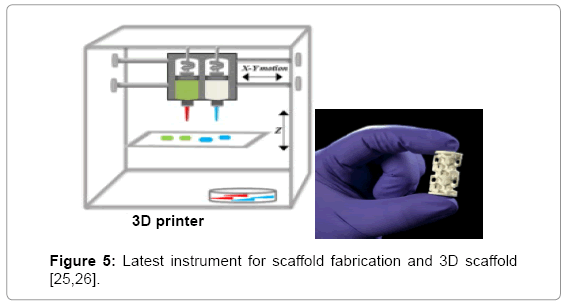

Improvements on these existing techniques, as well as new thermal processing methods for tissue engineering scaffolds, will be needed to provide tissue engineers with finer control over tissue and organ development.Biopolymers have been used as a replacement material for synthetic polymers in scaffold forming due to its biocompatibility and nontoxic properties. In this review, each tissue engineering scaffold preparation method is discussed, including recent advancements as well as advantages and disadvantages of the technique, with a particular emphasis placed on thermal parameters. Critical scaffold properties, including pore size, porosity, pore interconnectivity, and mechanical integrity, are determined by thermal processing parameters in many of these techniques. Existing techniques include fiber bonding, electrospinning, emulsion freeze drying, solvent casting/particulate leaching, gas foaming/particulate leaching, high pressure processing, and thermally induced phase separation. A wide variety of techniques have been developed to create both fibrous and porous scaffolds out of polymers, ceramics, metals, and composite materials. Tissue engineering requires complex three-dimensional scaffolds that mimic natural extracellular matrix function.

Journal of Manufacturing Science and Engineering.Journal of Engineering Materials and Technology.Journal of Engineering for Sustainable Buildings and Cities.Journal of Engineering for Gas Turbines and Power.Journal of Engineering and Science in Medical Diagnostics and Therapy.Journal of Electrochemical Energy Conversion and Storage.Journal of Dynamic Systems, Measurement, and Control.Journal of Computing and Information Science in Engineering.Journal of Computational and Nonlinear Dynamics.Journal of Autonomous Vehicles and Systems.ASME Letters in Dynamic Systems and Control.

ASCE-ASME Journal of Risk and Uncertainty in Engineering Systems, Part B: Mechanical Engineering.Mechanical Engineering Magazine Select Articles.

0 kommentar(er)

0 kommentar(er)